SIMEON SHAW - 1829

Simeon Shaw, in his History of the North Staffordshire Potteries, written in 1829, described the filth produced by the bottle ovens:

"The vast volumes of smoke and vapours from the ovens, entering the atmosphere, produced that dense white cloud, which from about eight o'clock till twelve on the Saturday morning, (the time of firing-up, as it is called,) so completely enveloped the whole of the interior of the town, as to cause persons often to run against each other; travellers to mistake the road and strangers have mentioned it as extremely disagreeable, and not unlike the smoke of Etna and Vesuvius."

CHARLES DICKENS - A PLATED ARTICLE - 1852

'A Plated Article' is a story by Charles Dickens. It was published in his famous magazine 'Household Words' in 1852 after a tour of the Spode Factory, then under the ownership of W. T. Copeland in Stoke. He wrote it from the point of view of a Willow pattern plate made at the factory. He includes literary references as well as comparing unusual aspects of the pottery industry with everyday objects of the period.

| Charles Dickens |

'... Don't you remember (says the plate) how you steamed away, [travelling by steam train] yesterday morning, in the bright sun and the east wind, along the valley of the sparkling Trent? Don't you recollect how many kilns you flew past, looking like the bowls of gigantic tobacco-pipes, cut short off from the stem and turned upside down?

'And the fires - and the smoke - and the roads made with bits of crockery, as if all the plates and dishes in the civilised world had been Macadamised, expressly for the laming of all the horses? Of course I do!

'And don't you remember (says the plate) how you alighted at Stoke - a picturesque heap of houses, kilns, smoke, wharfs, canals, and river, lying (as was most appropriate) in a basin - and how, after climbing up the sides of the basin to look at the prospect, you trundled down again at a walking-match pace, and straight proceeded to my father's, Copeland's, where the whole of my family, high and low, rich and poor, are turned out upon the world from our nursery and seminary, covering some fourteen acres of ground? '

|

| Spode Willow pattern plate c1800 Photo: courtesy of Victoria and Albert Museum here> |

Dickens' description of firing '... And as to the Kilns, in which the firing takes place, and in which some of the more precious articles are burnt repeatedly, in various stages of their process towards completion, - as to the Kilns (says the plate, warming with the recollection), if you don't remember THEM with a horrible interest, what did you ever go to Copeland's for?

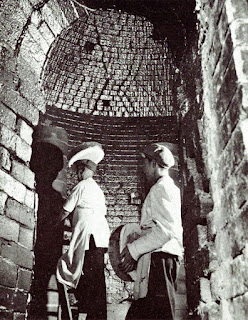

'When you stood inside of one of those inverted bowls of a Pre-Adamite tobacco-pipe, looking up at the blue sky through the open top far off, as you might have looked up from a well, sunk under the centre of the pavement of the Pantheon at Rome, had you the least idea where you were? And when you found yourself surrounded, in that dome-shaped cavern, by innumerable columns of an unearthly order of architecture, supporting nothing, and squeezed close together as if a Pre-Adamite Samson had taken a vast Hall in his arms and crushed it into the smallest possible space, had you the least idea what they were? No (says the plate), of course not!

'And when you found that each of those pillars was a pile of ingeniously made vessels of coarse clay - called Saggers - looking, when separate, like raised-pies for the table of the mighty Giant Blunderbore, and now all full of various articles of pottery ranged in them in baking order, the bottom of each vessel serving for the cover of the one below, and the whole Kiln rapidly filling with these, tier upon tier, until the last workman should have barely room to crawl out, before the closing of the jagged aperture in the wall and the kindling of the gradual fire; did you not stand amazed to think that all the year round these dread chambers are heating, white hot - and cooling - and filling - and emptying - and being bricked up - and broken open - humanly speaking, for ever and ever? To be sure you did!

| Spode Postcard c1970 The last remaining Spode oven collapsed in 1972 |

'And standing in one of those Kilns nearly full, and seeing a free crow shoot across the aperture a-top, and learning how the fire would wax hotter and hotter by slow degrees, and would cool similarly through a space of from forty to sixty hours, did no remembrance of the days when human clay was burnt oppress you? Yes. I think so! I suspect that some fancy of a fiery haze and a shortening breath, and a growing heat, and a gasping prayer; and a figure in black interposing between you and the sky (as figures in black are very apt to do), and looking down, before it grew too hot to look and live, upon the Heretic in his edifying agony - I say I suspect (says the plate) that some such fancy was pretty strong upon you when you went out into the air, and blessed God for the bright spring day and the degenerate times!'

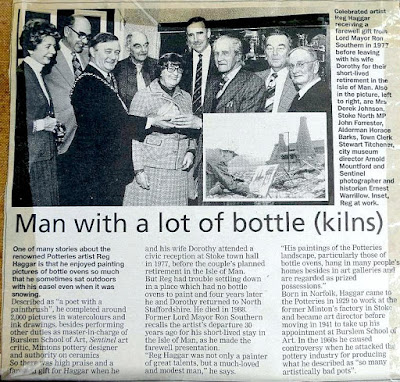

REGINALD G. HAGGAR, RA

LAST OF THE BOTTLE OVENS

"Bottle ovens have a peculiar fascination. No two of them are alike. They seem as full of character and offer as many surprises as human beings, and in temperament they are as volatile and unpredictable.The few that remain awaken special regard because their strange distorted but fantastically beautiful forms seem deeply imbued with the ardours of a past race of men who lived independent, passionate lives as crafts-men in clay and worked out their destinies by the unpredictable arts of fire. How ominous sounding is that old phrase by which men then reckoned their wages: "Good from oven".

Bottle ovens are remarkably varied in contour. Some are prim and severe, spinsterish even in line and appearance; others peculiarly curvaceous. The immense heat of the firing distorted their swelling curves, great fissures and cracks appeared, drastic surgery was necessary to preserve them, the brickwork was renewed and their great bellies were strapped round with girdles of iron to save them from collapse.

|

| Longton Elektra Porcelain Works Photo: source unknown Date: unknown |

This is the world of the Potter in which nearly all my working life as a creative designer and painter have been spent, and, in spite of the knowledge of what booms and slumps (and the collapse of Wall Street in 1930 was a traumatic experience) and the incredibly slow social and industrial revolutions have meant in terms of visual awareness - awful wastes of dereliction, appalling slums, slum houses, slum shops, slum factories, gaunt streets, death-inviting marl holes, glistening shraff tips, and the mantle and plumes of smoke I have come to love its splendours and miseries. This is one of the most haunting and in a curious way beautiful regions of the British Isles.

To capture a little of this beauty of shape and atmosphere, and to express what I feel about it has been my aim in painting pictures of the architecture of potter and pigeon-fancier and the waste lands in which they live, work and play."

To capture a little of this beauty of shape and atmosphere, and to express what I feel about it has been my aim in painting pictures of the architecture of potter and pigeon-fancier and the waste lands in which they live, work and play."

| Gladstone Pottery Museum from what is now the car park Water colour by Reginald G Haggar Photo: source Gladstone Pottery Museum |

1964 VISIONARY THOUGHTS

In October 1964, Reginald G. Haggar wrote to the Pottery Gazette and Glass Trade Review with his visionary thoughts about preserving a traditional old potbank for the benefit of future generations.

The editor of the Gazette wrote in ‘Topics’ on page 1083

"In our news pages Mr. Reginald Haggar, well-known author and artist, makes an impassioned plea for preservation of the historical Potteries in the form of bottle ovens (“beautiful”) and even a whole factory as a complete industrial museum. Those of us who love the area with all its character and idiosyncrasies would back his plea, and hope that something can be done to preserve the old, whilst acknowledging the benefit of modern methods in present-day production of the Six Towns."

A letter to The Pottery Gazette and Glass Trade Review

PRESERVING POTTERIES HISTORY

"Sir — The Potteries, as some of us knew it 30 years ago, is fast disappearing. The distinctive architecture of the Potteries towns, the bottle oven, is almost a thing of the past. The two or three thousand which existed then are now reduced to a couple of hundred or less, and, of these, not more than a score are still in operation.

It does not seem to be realised what beautiful things these bottle ovens were, the astonishing variety of contour, the queer and unusual bulges that resulted from the excess of heat, the varied manner of construction, the shaping of the neck and the almost battlemented edge. Some were heavily corseted, others still graceful spinsterish affairs which seemed so virginal as never to have trafficked with clay or fire.

You might come across a large nest of them at a street corner, or perhaps a lone slender cone at the end of a backyard. Now most of these have gone and the atmosphere is the cleaner and healthier for it.

For many years some of us have been urging the preservation not merely of an oven or two but of a whole factory which might be renovated and transformed into a live Potteries industrial museum and in which it might be possible for future generations to see how pots were made and decorated and fired in the days of Astbury and Whieldon and Wedgwood and Spode.

There they would see some of the original machines and tools and equipment. They would see also the astonishing variety of Potteries products, for in such a museum with its original warehouses it would be possible to display on a generous scale the prototypes of industry, moulds, models and machinery, and unusual pieces. One room might be used to house one example of every article made in this so diversified an industry.

Familiar things like the vessels comprised by dinner, breakfast and tea services would be there (and they run into thousands) but so too would many unfamiliar objects: the bell pulls, doorplates, key escutcheons and door knobs made by specialists in door furniture, the trinket sets that formerly adorned the dressing table and the toilet services for the obsolescent wash-tables, galley pots, whose name take us back to foreign trade in medieval times, creel steps and shuttle eyes made for Manchester cotton spinners. marbles and taws for children and parlour bowls for Victorian grown ups, nest eggs for poultry farmers, porcelain teeth, ceramic buttons, and a thousand other things.

At such a museum it would be possible to trace the history of tea drinking and all the weird and wonderful patents for brewing tea in a teapot, or the evolution of electrical equipment or the development of the water closet.

An old factory transformed into a live museum, that is the idea and year by year one sees the disappearance of desirable factories. Some have gone almost overnight: the factory at Longport with its original Georgian house; the Victoria works at Fenton which was worked by Miles Mason when he abandoned trade as a Chinaman and the adjoining house where he lived; the great ovens and workshops of the old Bedford Works at Shelton where, if it had been preserved, it might have been possible to moor a long boat gay with castles and roses and all its equipment; the factory at Greenhead, Burslem; and so on.

One great factory still survives more or less intact as far as its façade is concerned, although. I believe the ovens are no more, the factory which Josiah Wedgwood built by the canal in the valley between Burslem, Hanley and Newcastle. The scene today is grim: then, with its village of workers’ houses, its little inn and the master's house it must have been rather fine, a prototype for an industrial settlement.

At Etruria, industrial and social history are enshrined. There is another eighteenth century factory at Cobridge, a smaller but not less attractive one, with its original bell turret and many surviving old workshops.

At Longton there is a derelict factory of great age, the Pelican works I believe it is called, which holds the eye because of its diminutive scale. It stands at the end of Sutherland Road and its original entrance was at the corner where a draper’s shop now stands. A long low building on shelving ground so that from one side it scans even lower than it is, and above the roofs poke the broad mouths of the hungry ovens. Broken windows afford glimpses of decay and dereliction which the imagination changes into a flurry of human activity.

Further along are the great bastilles of the Industrial Revolution, the great gaunt factories built on shordrucks, and above them higher still the lordly ovens flaunting their curves over the rooftops. Longton is still relatively full of history.

It is still not too late, therefore, to preserve something of the history of this great industry for future generations. Cannot something be done about it before the landmarks of the Industrial Revolution disappear or decay beyond repair?"

Reginald G. Haggar, October 1964

| Sampson Smith's Pottery and Garfield Works, Longton demolition Water colour by Reginald G Haggar Photo: Private Collection |

1965 MORE VISIONARY THOUGHTS

On 9th April 1965 Reginald Haggar wrote a piece for the Evening Sentinel.

Extract:

'CITY SHOULD PRESERVE BEST OF OLD BUILDINGS'

An exhaustive survey of Stoke-on-Trent’s industrial archaeology was advocated by Mr. Reginald Haggar during a lecture at Shelton last night. The survey should be undertaken swiftly to see what was worth preserving and how the buildings, if preserved, could play a useful - spiritual as well as utilitarian - part in the city’s future life.

“Let me say that this kind of survey would have a specific end in view - the preservation of worthwhile and potentially viable fabrics” explained Mr Haggar. “Among the things which might be preserved,” he suggested, “were factory facades, bottle ovens, inns, shops, chapels, canals, bridges, railway stations and tunnels.”

Mr Haggar continued “Why should these things be preserved, and remember, I have said they cannot and should not be preserved unless they can be integrated effectively into the life of the 20th century?” He went on, “Because from the ways and habits and modes of living and working in the past we may learn lessons of how to live together and work together in the present and the future.”

“Because when we look back on the buildings of our past we are reminded, if only faintly, of what they went through and suffered in order that we might survive. Because out of such darkness and dirt so much beauty, sheer beauty, was created.

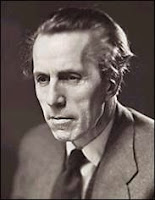

Reginald G Haggar

Reginald George Haggar (1905–1988) R.A., A.R.C.A., F.R.S.A. was a significant British ceramic designer. He was born in Ipswich and studied at Ipswich School of Art and the Royal College of Art. In 1929, he became assistant designer at Mintons pottery in Stoke-on-Trent, rising to art director six months later, a post he held until 1939. Working in water colours and ceramics, his designs reflected both the radical and lyrical elements of the Art Deco style. After leaving Mintons, he became Master-in-Charge of the Stoke School of Art to 1941 and then of Burslem School of Art until 1945. He was an artist and lecturer in the Potteries area. He painted many pictures of North Staffordshire.

Reginald George Haggar (1905–1988) R.A., A.R.C.A., F.R.S.A. was a significant British ceramic designer. He was born in Ipswich and studied at Ipswich School of Art and the Royal College of Art. In 1929, he became assistant designer at Mintons pottery in Stoke-on-Trent, rising to art director six months later, a post he held until 1939. Working in water colours and ceramics, his designs reflected both the radical and lyrical elements of the Art Deco style. After leaving Mintons, he became Master-in-Charge of the Stoke School of Art to 1941 and then of Burslem School of Art until 1945. He was an artist and lecturer in the Potteries area. He painted many pictures of North Staffordshire.

|

| Reginald G. Haggar (1905-1988) |

|

| Sutherland Road, Longton Looking up towards Garfield Works Water colour by Reginald G Haggar Photo: Private Collection |

|

| Reginald G Haggar - article from The Evening Sentinel |

SANDEMAN - THE MANUFACTURE OF EARTHENWARE - 1901

In 1901 Ernest Albert Sandeman (1860 - ? ) wrote a quite remarkable book "Notes on The Manufacture of Earthenware"

The book runs to 375 pages in 31 chapters and includes all of the manufacturing processes for earthenware. It was reprinted in 1917 and again in 1921.

Ten of the chapters are dedicated to the building of bottle ovens, the making of saggars, how bottle ovens were fired, to biscuit and to glost. It's a great background to bottle ovens.

| Notes on the Manufacture of Earthenware Ernest Albert Sandeman 1901,1917 and 1921 |

The book is freely available to view on the web and the entire book is downloadable here>> at The Internet Archive.

Here is an extract from Sandeman's book giving details of bottle ovens and their firing in the first quarter of the 20th Century. Download here>>

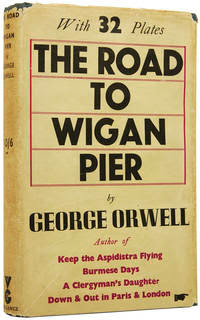

GEORGE ORWELL - THE ROAD TO WIGAN PIER - 1937

Extract from his book “The pottery towns are almost equally ugly in a pettier way [than Sheffield]. Right in among the rows of tiny blackened houses, part of the street as it were, are the ‘pot banks’— conical brick chimneys like gigantic burgundy bottles buried in the soil and belching their smoke almost in your face.

You come upon monstrous clay chasms hundreds of feet across and almost as deep, with little rusty tubs creeping on chain railways up one side, and on the other workmen clinging like samphire-gatherers and cutting into the face of the cliff with their picks.

I passed that way in snowy weather, and even the snow was black. The best thing one can say for the pottery towns is that they are fairly small and stop abruptly. Less than ten miles away you can stand in un-defiled country, on the almost naked hills, and the pottery towns are only a smudge in the distance.

When you contemplate such ugliness as this, there are two questions that strike you. First, is it inevitable? Secondly, does it matter?

I do not believe that there is anything inherently and unavoidably ugly about industrialism. A factory or even a gasworks is not obliged of its own nature to be ugly, any more than a palace or a dog-kennel or a cathedral. It all depends on the architectural tradition of the period. The industrial towns of the North are ugly because they happen to have been built at a time when modern methods of steel-construction and smoke-abatement were unknown, and when everyone was too busy making money to think about anything else. They go on being ugly largely because the Northerners have got used to that kind of thing and do not notice it.”

George Orwell, 1903-1950

George Orwell was the pen name used by British author and journalist Eric Arthur Blair. During most of his professional life time Orwell was best known for his journalism, both in the British press and in books such as Homage to Catalonia, describing his activities during the Spanish Civil War, and Down and Out in Paris and London, describing a period of poverty in these cities. Orwell is best remembered today for two of his novels, Animal Farm and Nineteen Eighty-Four.

SIR GEORGE WADE - THE BOTTLE OVEN

The bottle ovens which for generations have been such a dominating feature of the Potteries landscape are rapidly vanishing, and soon there will be none at all. This is a very sad reflection for old potters like myself who remember the days when there was no other kind of oven but the majestic bottle type.All bottle ovens, even when built to the same plan and specification, were different. They all had temperaments and mostly female at that! To get them to produce good ware one had to coax, humour, even to love them! A change of wind, weather, humidity or fuel would upset them thoroughly with consequent loss of ware, due to nothing, so the fireman would assure you, but bloody-mindedness on the oven's part.

A bottle oven would last for a century, but it would keep its character all that time in spite of modifications Some of them were respected, others were feared, and some were absolutely hated and were known by rude names.

|

| 'Placing' or 'setting-in' the glost bottle oven Photo: Source unknown Date: 1950s |

Now to the operation of a bottle oven. When all the precious saggars had been placed and the clammins built up, fires were started in each mouth with oil soaked rags and odd pieces of wood on which were placed cobbles of coal steadily built up into a fire.

To look into the oven through the spyhole at this stage was a miserable experience; a flickering light from each 'bag' just enabling you to see the wisps of smoke and the condensation running down the bungs of cold saggars. Everything appeared cold, wet and hopeless, but when you looked in a few hours later what a change! A beautiful radiance emanated from every part of the inside. No smoke could be seen, everything was one solid mass of rosy heat. Damn Blastus (the god of Potting) had established himself in his temple and the steady draught which was drawn through the oven sounded like a deep organ note. The trial rings could dimly be seen leaning against one another at an angle, and it required no small dexterity to put in the trial rod, seven or eight feet of half inch round iron, hook out one trial and get the rod out before it started to melt and bend.

With infinite care the baitings were put on leaving a critical space over the top of the coal varying with the requirements of each part of the oven as revealed by the measurement of the trial rings. Dampers and air inlets were all carefully controlled, and steadily the temperature of the tons of saggars and ware rose towards the finishing point. Finally came the ‘soaking’ period when the top temperatures were maintained to get even distribution throughout the oven.

Then the giant oven would be left to cool down after its labours, and anxious people would be eagerly awaiting what would be revealed when it was 'drawn' a day or two later.

Would the ware that was not too 'hard fired' owing to too high a firing temperature be too 'easy fired' having not been fired hard enough, and if it were neither hard nor easy, how much would have 'dunted' that is cracked during cooling? And if it had not been too hard or too easy fired, or dunted how much would be 'reduced' to a blue colour by too much smoke? And out of any ware which had not been easy or hard or dunted or reduced, how much would be 'flashed' by too quick firing? And out of that ware which had safely survived easy firing, hard firing or dunting or reduction or flashing, how much would have brown spots on?

Those were only a few things on ones mind until a biscuit oven was emptied, but what about a 'glost'

oven? To all the above hazards add for glazed ware: Would it survive the crazing test? Would the colours be smeared by sulphur? Would the cobalt colours ‘strike' their innocent neighbours by volatilizing a blue tinge on to them? Would the glazes run down and stick? Would they be 'smoked'?

Who would be a potter!?

The above puts me in mind of the new Natural Law which the late Dr Mellor discovered as a result of his studies of the Pottery Industry. He called it THE LAW OF THE INNATE CUSSEDNESS OF INANIMATE OBJECTS which operates like this:

If there is a single blemish on an important piece of pottery it is always in the most prominent part, if you over fire part of an oven and spoil the ware, it is always a most overdue order for your most important customer who has already been let down three times, and so on and so on.

Slight manifestations of Mellor's Law have been noticed in other industries, but the sublime examples of it come from the old bottle ovens which were truly selective in their misdeeds.

Soon all the bottle ovens will be gone and with them will vanish men I much admire - the Placers and the Firemen.

The Placers had to be men of superb physique who could carry a saggar weighing 60 to 70 lb up a high 'horse' and place it with unerring precision on top of a bung of saggars so that it was vertically and horizontally true. They worked like beavers under dismal conditions and considerable risk, and had a team spirit and sense of responsibility which was admirable in the extreme.

The Firemen were the Arch Druids of the factory, their word was law. Theirs was the responsibility of submitting the whole output to the test of the flames, They could make or mar a business, they could ruin or keep in work hundreds of people.

They were patient, knowledgeable, reliable and firm. Woe betide the boss who wanted to alter the firing cycle to save a little coal. "No sir, if we shorten the time we shall get smoked ware. All right sir, if you say so, I must, but don't say I didn't warn you.

Out would come smoked ware alright and the fireman's reputation would be enhanced. Of course the boss being in bed at 3am had not seen him close off all the dampers for a longer period than usual. Yes they had their ways, but as a class they were unbeatable for trustworthiness, reliability and skill.

Sir George Albert Wade (19 July 1891 – 27 January 1986), born in Burslem, Stoke-on-Trent, to a family who ran a pottery business. He was knighted in 1955 for political and public services. Sir George was a pupil at Newcastle High School, which had been amalgamated into the Newcastle-under-Lyme School, and left at age 15 to work at the family's pottery factory. He was a soldier between 1914 and 1919 in World War I, first as a private with the North Staffordshire Regiment, and then as a lieutenant with the South Staffordshire Regiment in the Machine Gun Corps, and he served in France and Egypt. Sir George became chairman of the family's pottery business, Wade Ceramics Ltd, a manufacturer of porcelain and earthenware, whose main factory was in Burslem, Stoke-on-Trent. In the 1950s, Sir George and the Wade potteries created and manufactured "Whimsies", small cheap solid porcelain animal figures, which became popular and collectable in Britain and America.

A firing chamber and a fuel are needed to raise the clay to a temperature above about 600ºC when the irreversible chemical changes take place and the soft mud becomes a brittle, hard pot. Dr. Plot described the ovens he saw in use in Burslem in 1686, ordinarily above 8 foot high, and about 6 foot wide, of a round copped forme. He was describing the business part, the domed, 'beehive' shaped firing chamber which was protected by the addition of a hovel in the shape of a bottle, as the 18th century progressed.

Bottle ovens were the iconic building for firing ceramics, offering storage and working space for fuel, ware and saggars and protection for all, including the firing chamber itself. The tall chimney of the bottle form was ideal for venting the smoke and other gases.

It is thought that wood was used in the early days of the 'round copped forme' but in Staffordshire the abundant supply of coal made pottery production a natural industry of the area, with the consequence of black smoke, produced whenever the firemouths were baited or fed with coal. It is important to realise that to fire one ton of domestic clay-ware in a bottle oven between seventeen and twenty tons of coal would be used.

KATHY NIBLETT BA AMA FRSA - EARTHENWARE AND BOTTLE OVENS - 2006

Part of an essay for CLAYART in WALES, 2006

Our beautiful body, [earthenware] shaped and possibly decorated, is nothing until baked.

A firing chamber and a fuel are needed to raise the clay to a temperature above about 600ºC when the irreversible chemical changes take place and the soft mud becomes a brittle, hard pot. Dr. Plot described the ovens he saw in use in Burslem in 1686, ordinarily above 8 foot high, and about 6 foot wide, of a round copped forme. He was describing the business part, the domed, 'beehive' shaped firing chamber which was protected by the addition of a hovel in the shape of a bottle, as the 18th century progressed.

Bottle ovens were the iconic building for firing ceramics, offering storage and working space for fuel, ware and saggars and protection for all, including the firing chamber itself. The tall chimney of the bottle form was ideal for venting the smoke and other gases.

It is thought that wood was used in the early days of the 'round copped forme' but in Staffordshire the abundant supply of coal made pottery production a natural industry of the area, with the consequence of black smoke, produced whenever the firemouths were baited or fed with coal. It is important to realise that to fire one ton of domestic clay-ware in a bottle oven between seventeen and twenty tons of coal would be used.

Pots were subjected to awful conditions in the chamber. Temperature, over many hours, smoke and gases, particularly sulphur given off by some coals, could seriously injure their surfaces and to avoid this, ware was placed in protective boxes, made of marl, not clay and called saggars. Saggars were stacked in bungs, tall columns in the firing chamber, attention being paid by the cod placer, the chief placer, to the siting of contents according to the hot spots.

As Robert Plot said: they doe not expose them to the naked fire, but put them in shragers, … to preserve them from the vehemence of the fire, which else would melt them downe, or at least warp them.

Bottle ovens were built all over Britain, wherever pottery was made. In 1945 there were about 2000 bottle shaped structures in Stoke-on-Trent, not all potters' ovens, some were structures used by potters' millers in the preparation of raw materials, flint and animal bone.

The Clean Air Act of 1956, enacted in 1958, sounded the death-knell of the coal-consuming, black-smoke belching giants, which dominated the landscape of the Potteries. Their architecture gives a romantic appeal but to work with a bottle oven was back-breaking and seriously injurious to the health of workers and the people of the district.

Arnold Bennett described their impact well in his novel The Old Wives Tale:

The Clean Air Act of 1956, enacted in 1958, sounded the death-knell of the coal-consuming, black-smoke belching giants, which dominated the landscape of the Potteries. Their architecture gives a romantic appeal but to work with a bottle oven was back-breaking and seriously injurious to the health of workers and the people of the district.

Arnold Bennett described their impact well in his novel The Old Wives Tale:

The Five Towns … are unique and indispensable. … the architecture of the Five Towns is an architecture of ovens and chimneys; … its atmosphere is as black as its mud; it burns and smokes all night, … it is unlearned in the ways of agriculture, never having seen corn except as packing straw … it comprehends the mysterious habits of fire and pure, sterile earth; … it lives crammed together in slippery streets where the housewife must change white window-curtains at least once a fortnight if she wishes to remain respectable; … it exists – that you may drink tea out of a teacup and toy with a chop on a plate.

In Stoke-on-Trent today, forty-seven bottle shapes remain to tell the tale of past glories and horrors. Although all are Listed, many are in a dreadful condition and demolition by neglect will surely follow. There are honourable exceptions and owners take their responsibilities very seriously. It is no easy task to maintain a bottle oven since the shape and size (up to 70 feet high) offer challenges to all but steeplejacks. How can you 'weed' a garden in the sky? These 'buildings' were always warm so that now rain and frost take their toll with every passing winter. No bottle ovens survive in Tunstall, the most northerly of the Six Towns. The only down draught survivors in the City, are in a perilous state, in Burslem.

The last commercial firings of bottle ovens in Stoke-on-Trent took place in the-mid 1960s. In 1978 a coal firing was arranged by Gladstone Pottery Museum so that a film record could be made before all structures were unsafe and whilst the men who had the skills could revive their talents and direct a team of ignorant volunteers. It was an amazing week.

© Kathy Niblett 2006

Kathy Niblett has asserted her right to be identified as the author of this work in accordance with the Copyright, Designs and Patents Act 1988

The bottle oven which is most easy to describe and understand is basically a structure in two parts.

The firing chamber is a tall cylinder built with refractory (fire-resistant bricks) with a domed roof called the crown. It has one doorway known as a wicket or the clammins and around the base are the fire mouths.

This firing chamber is protected by the hovel - the bottle shaped, brick-built structure which gives it its name. Its shape is exactly like the old fashioned milk bottle with straight sides from ground to above the crown .

Very few processes were carried on within the hovel and so, little space was required.

The hovel oven could be used to fire both biscuit and glost ware - the first and second firings of undecorated product. This type of oven is likely to be an updraught oven.

From the fire mouths there are flues running under the floor to the centre of the firing chamber and on the inner wall immediately above the fire mouths are the bags, which are like small chimneys. The flues and the bags ensure that the heat is distributed to all parts of the firing chamber. Naturally the spots near to the bags are hotter than in other parts. One of the skills of the cod placer, the man in charge of placing the oven, was to place the right product in the right place according to its need for a hotter or cooler firing.

The floor of the firing chamber rises slightly to the centre where all the under-floor flues meet in the well-hole. Above this hole a chimney is built, called the pipe bung, as the oven is filled. Saggars, without bases, are placed one on top of the other. The heat, gases and smoke rise through the setting and escape through the crown and up the chimney.

Kathy Niblett - February 1998

Author of 'The Mighty Bottle Oven' 1998, City Museum and Art Gallery, now Potteries Museum and Art Gallery.

© Kathy Niblett 2006

Kathy Niblett has asserted her right to be identified as the author of this work in accordance with the Copyright, Designs and Patents Act 1988

KATHY NIBLETT BA AMA FRSA - THE MIGHTY BOTTLE OVEN - A description - 1998

|

| The Mighty Bottle Oven Gladstone Pottery Museum, Longton Photo: Terry Woolliscroft Collection Date: May 2018 |

The bottle oven which is most easy to describe and understand is basically a structure in two parts.

The firing chamber is a tall cylinder built with refractory (fire-resistant bricks) with a domed roof called the crown. It has one doorway known as a wicket or the clammins and around the base are the fire mouths.

This firing chamber is protected by the hovel - the bottle shaped, brick-built structure which gives it its name. Its shape is exactly like the old fashioned milk bottle with straight sides from ground to above the crown .

Very few processes were carried on within the hovel and so, little space was required.

|

| Cross section through an updraught bottle oven Shows flues from bags to well hole Image: Phil Rowley |

From the fire mouths there are flues running under the floor to the centre of the firing chamber and on the inner wall immediately above the fire mouths are the bags, which are like small chimneys. The flues and the bags ensure that the heat is distributed to all parts of the firing chamber. Naturally the spots near to the bags are hotter than in other parts. One of the skills of the cod placer, the man in charge of placing the oven, was to place the right product in the right place according to its need for a hotter or cooler firing.

Kathy Niblett - February 1998

Author of 'The Mighty Bottle Oven' 1998, City Museum and Art Gallery, now Potteries Museum and Art Gallery.