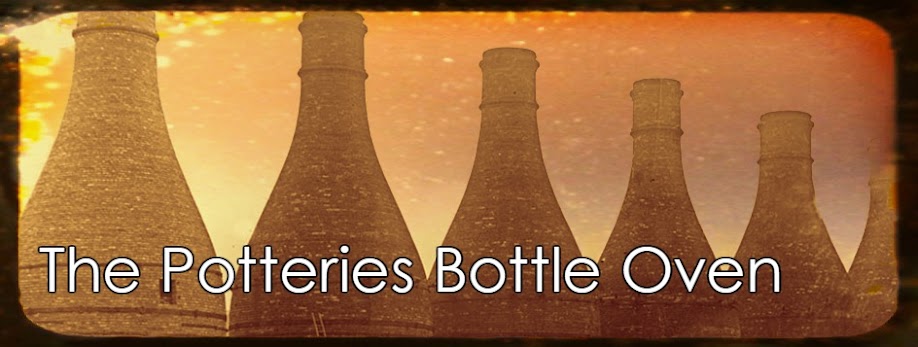

Huge, towering and complex brick-built bottle ovens and kilns, integral to a potbank and an essential tool in pottery manufacture, were once the dominant feature of the Potteries landscape.

|

| Bottle ovens landscape, in art "Seven Sisters" J & G Meakin Ltd., Eastwood Works, Lichfield Street, Hanley. Terry Woolliscroft Collection |

Bottle Ovens 1954

46 seconds from the film called 'The Peak District'

Thick, black, choking smoke always filled the air.

Sooty smuts clung to everything.

The Clean Air Act of 1956 finally put a stop to their use and sealed the fate of the traditional coal-fired oven. Pottery manufacturers were forced to change but allowed seven years to fully adapt to the alternative methods and fuels.

By 1960 there were less than 200 operable coal-fired bottle ovens.

Interestingly, throughout the whole of the UK, fewer than 100 pottery oven and kiln structures remain. More details here>

By 1960 there were less than 200 operable coal-fired bottle ovens.

By July 1963 all bottle ovens and kilns were redundant, although just a few were used after the deadline. The skills of the people who used them were redundant too. Their skills faded away. The rush to demolish, encouraged by the local council, began in earnest.

In 2023 fewer than 50 precious examples remain standing complete with their bottle-shaped chimney.

In 2023 fewer than 50 precious examples remain standing complete with their bottle-shaped chimney.

Of these only 30 are potters' ovens, used for biscuit or glost firing. 18 of these are within a very short walk of Gladstone Pottery Museum in Longton, the southernmost of Stoke-on-Trent's six towns.

Interestingly, throughout the whole of the UK, fewer than 100 pottery oven and kiln structures remain. More details here>